About Company

Our Directors

ABOUT Company

We are Indore Based, Manufacturing unit of UHMWPE Sheets, Components, Rods, Rollers and Pipes in India. POLYTRON, GLIDER and POLYPICK are our registered brand of UHMW PE Products. We started our manufacturing unit in the year 2008 with the maximum sheet length of 8 Meter. This length is still the longest in INDIA. With the demand in bigger width and small length, we took an expansion with another Size 1000 X 2000 MM. This size is convenient in most of the applications.

Further, to add our range, we also started making profiles using Extruders. The Extruders for UHMW PE is a unique technology. The Extruded profile makes the life easier for both user and manufacturer. We can extrude any shape as per user’s design.

With the growing demands of UHMWPE sheets, there is the requirement of broader width and higher quantity. We had further expanded to the size 1250 X 5500 MM with world’s latest technology. The new technology made the production faster and better in terms of quality. UHMW PE is still an underutilize product in India. The latest technology of making different things in UHMW PE is difficult and expensive to source. With the entry of Global Players in India, it was need of an

hour to increase production, quality and range of products.

To explore the various applications and true properties of UHMWPE, we have started manufacturing UHMW PE Rollers and Pipes. Pipe and Rollers are unique range and has got lot of potential to reduce the cost of our customers.

With entire extruders and sheet manufacturing facilities, our annual installed capacity has become 1200 Ton. This has lead us to faster delivery of world class products.

Our Production Range:

ANNUAL PRODUCTION CAPACITY: 1200 Ton ONLY UHMW PE

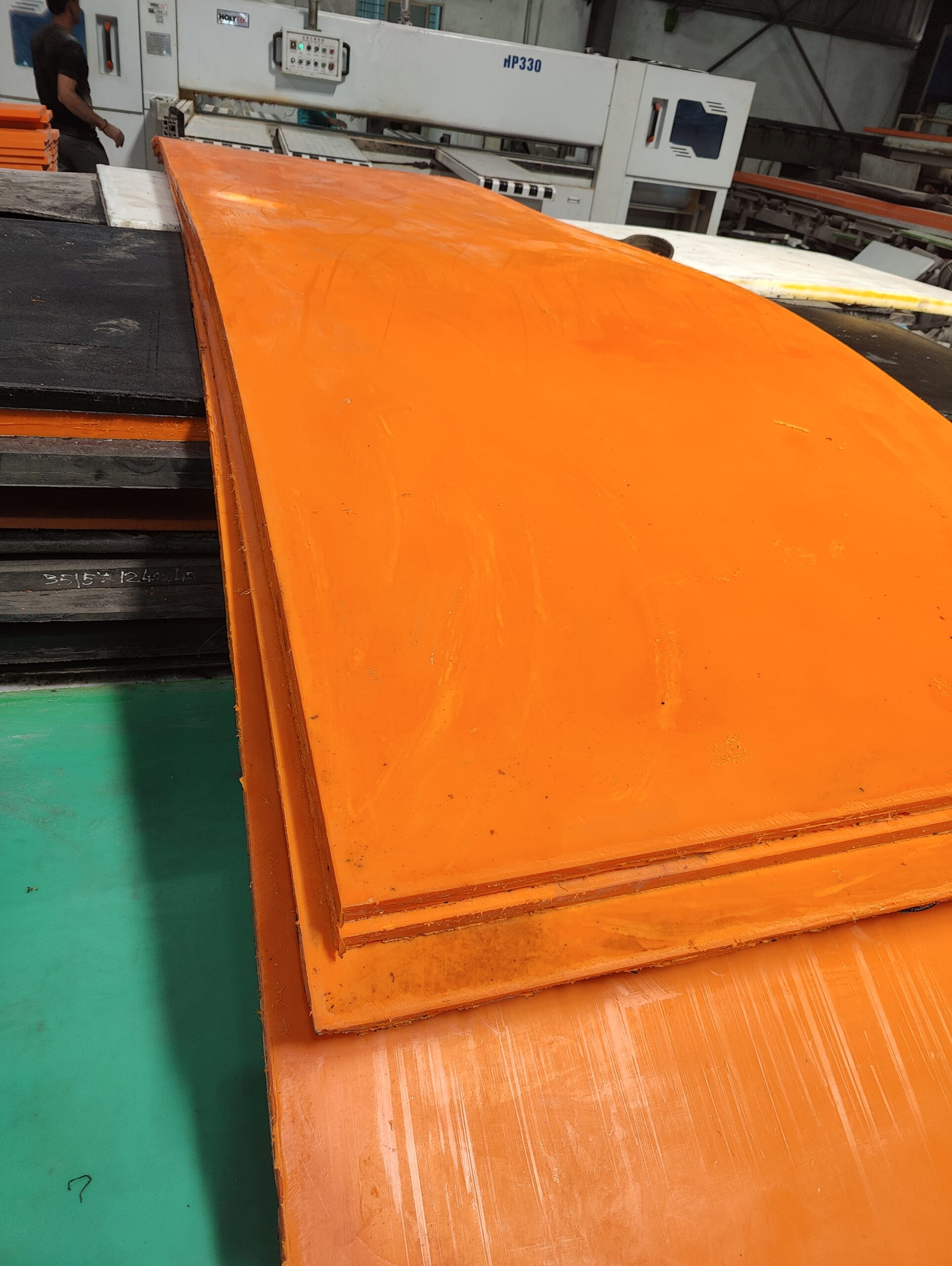

Sheets:

1000 X 2000 MM

1250 X 5500 MM

Thickness: 8 to 200 MM

Color: Natural White, Green, Orange, Yellow, Black, Red

Profiles: C / U / L / B2 / Customized

Pipe & Rollers: 50, 90, 102, 108, 114, 133, 140, 152, 160 MM

Machines : Hydraulic Presses, RAM Extrusions, Screw Extrusions

We have state of art CNC Machines, Routers, Cutters, Lathes, Milling, Planner and Finishing machines to serve you as per your drawing. We have professional and experienced professionals to keep check on quality and delivery of material.

Our

Product

- Polymer Liners – Silos, Hoppers

- The Silos, Hoppers are often choked by the moisture present in the carrying material. This decreases the material flow and gradually jams the entire process. The Corrosive material corrodes the body and needs frequent replacement. The POLYPICK UHMW PE Sheets are used to line the surface to have smooth flow in. With very high impact strength, this Polymer liners safeguard the main body and can easily be replaced.

- Truck Bed Liner

- Tip Trailers, Dumpers are mostly used in transporting the Moisture/Wet material. The wet material sticks on metal body and sometimes causes tip over. The accident may cause human loss along with machine. In case of Chemical transportation like lime ash, pond ash, salt etc, the vehicle body needs frequent replacement. POLYPICK UHMWPE liners are non-sticky, high abrasion resistance and easy to clean.

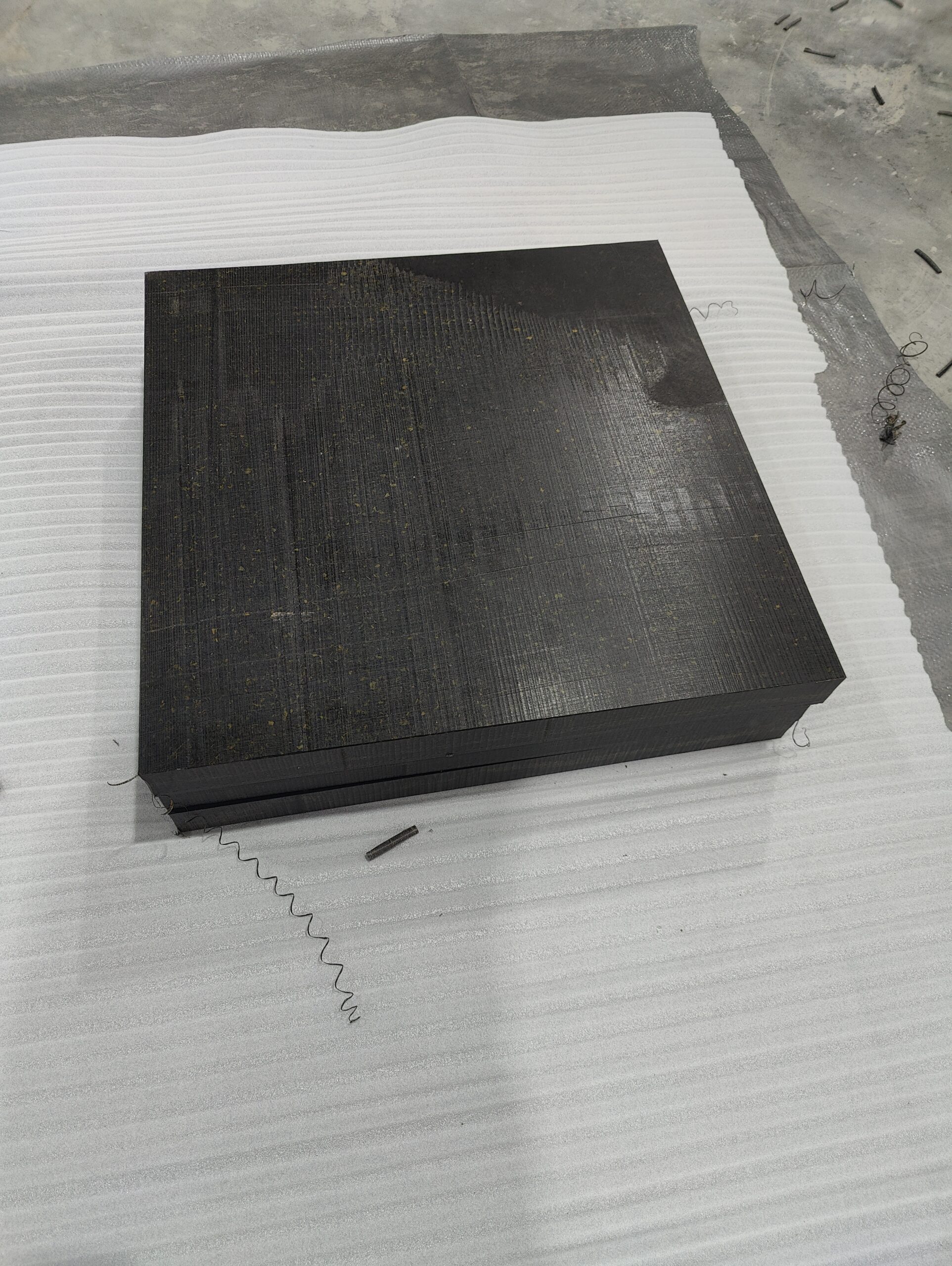

- Pressure Pads for Steel Plants

- Pressure pads are widely used to avoid metal to metal friction and longer life. The most Cold Rolling Mills in India, have shifted from traditional wood block to highly stable UHMW PE.

- Dewatering Elements for Paper and Asbestos Sheets

- De-watering Elements, known as tops of wire part, usually made of POLYTRON to avoid the fast wearing of tops and wire. The wire moves at speed from 100 to 500 Meter Per Min, 24X7. Tops which come under direct contact of wire, must be of very good quality else it would damage the wire. We have range of quality for varied speed of machines.

- Solid Liquid Separation / Horizontal Belt Filter – Seal Strips

- Sealing strips are used in vacuum system / horizontal belt filters in separating systems. The continuous movement of filter clothe require sealing strip to be chemical inert with lowest coefficient of friction. The Polytron UHMW PE strips and rounds are best suited material in such critical applications.

- Gas Plants - Antistatic Strips

- LPG Bottling plants are having the conveyors to transfer the bottles. The conveyor strip has to be antistatic to absorb the current generated due to friction. The POLYTRON UHMW PE anti-static strips also wear slowly and avoid metal to metal contact in the bottom and sides of conveyor line. The various components are also being used in gas filling plants.

- Dock Fenders –FACIA PADS

- Facia Pads are made of POLYTRON UHMWPE Sheets to absorb the high impact of ships, wear resistance and to survive in sea water. The frontal frame which is usually made of SS and Rubber contains POLYTRON UHMW PE as facia pads in Virgin and Commercial grades. It also works in freezing conditions in cold countries.

- Profiles for Bottling Plant and Conveyor Systems

- The bottling plant contains lot of star wheel, guide, curves where other materials cannot perform. The easy machinability of POLYTRON and smooth glide makes it perfect choice for automated bottling parts.

- Outrigger Pads

- UHMW PE outrigger pads offer a combination of strength, durability, and ease of use that makes them an excellent choice for many applications. Their lightweight nature and long service life make them particularly appealing for mobile operations where equipment needs to be set up and taken down frequently.

- Temporary Roads

- Temporary roads made of UHMW PE (Ultra-High Molecular Weight Polyethylene) sheets are an innovative solution for various industries and applications. UHMW PE sheets for temporary roads offer a unique solution that combines durability, environmental friendliness, and ease of use. They are particularly valuable in situations where minimal ground disturbance is crucial or where rapid deployment and removal of access roads is necessary.

- UHMW PE Rollers and Idlers

- Glider rollers, made of UHMW PE, is an INNOVATIVE products, very useful in extreme conditions. Glider, The import substitute is a taken by most of the customer with open hearts to make the conveying more efficiently. Low wear, High Impact Strength and anti sticking properties are being exploited fully to effectively use the UHMW PE Rollers. The life of UHMW PE Glider Roller is very high as compare to Metal or any other plastic Roller.

- General Engineering

- Polypick UHMW PE components are widely used in general engineering application. Bushes, Guides, Strip, Sleeves, sheets are commonly used product in almost every engineering machine. The versatility of the UHMW PE makes it an ideal choice for various components.

About US

It is a story of a wounded father and a frustrated son. It is all about regain the lost glory. It is the result of hard work and passion to re-create a business from dawn to dusk. POLYTRON, is the symbol of never say die attitude. It is the story where you may find yourself, in some or other way. The Father – Mr BK Moondra, a Mechanical Engineering graduate of 1971, is an entrepreneur since beginning. After successfully running the industries for 25 years, he got bitten in Partnership Companies. The son Rahul, BE Comp and MBA Finance, had unfulfilled dream of being an Industrialist, served in corporates for 9 years. The hunger of success was very high in both the minds.

It was the Year 2007, when the duo of father and son, conceived to start the UHMWPE business again. You get the new technology of any production unit in every 5 years. It was long 15 years when he last did it. It was the challenge to find the latest technology in the field of UHMWPE. The young blood and seasoned businessman started the production in FEB 2008 after searching and analyzing the right technology. In next 5 years, POLYTRON reached to a large customer base and soon planned for first expansion.

The youngest son GAURAV, MBA Marketing, also left his 10 years corporate career and joined the family business to take it to the new heights. With the entry of Mr Gaurav, it became a TRIO and his expertise and in-depth knowledge of Marketing, Sales and Brand Building, the company has taken the booming path of growth and Success. Just when, company started to peak, a massive fire had put the breaks in its growth. The Night of 1 April 2013 had vanished most of the plant, stock and building but couldn’t burn the passion of family. In next 45 days, Polytron was up and running. It is

purely a family run business with the mix of corporate and experienced professionals.

Dealing with us, you will connect yourself with us and would be comfortable with the intent of POLYTRON Family. It is not only our Professionalism but also relationship with you which built trust and faith in our business.