Bulk Material

UHMW PE (Ultra-High Molecular Weight Polyethylene) plays a significant role in bulk material handling across various industries due to its exceptional properties. Here’s a comprehensive overview of its usage in this field:

1. Conveyor Systems:

- Belt support: UHMW PE slider beds and impact beds.

- Skirting: To contain material and reduce dust.

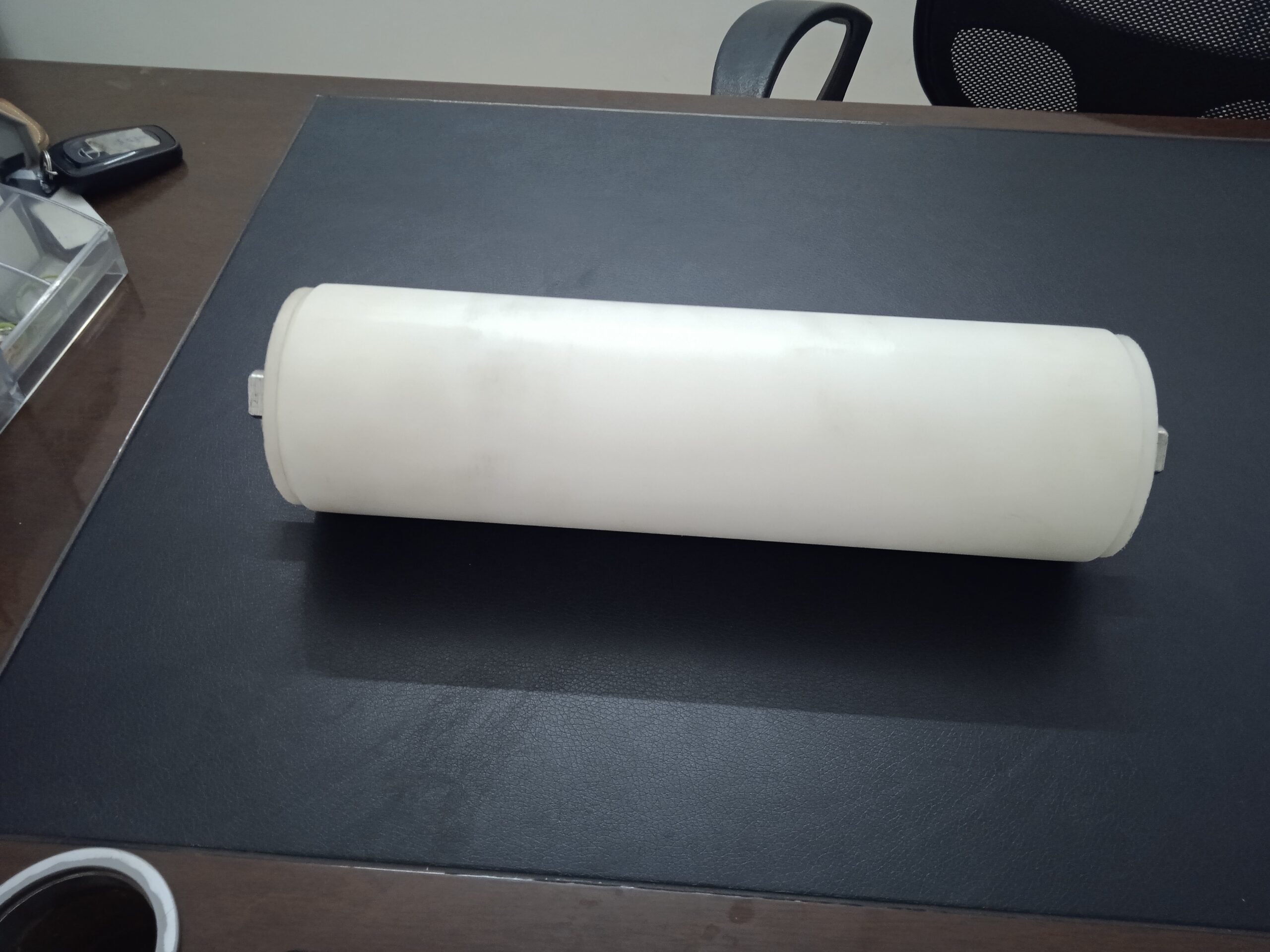

- Rollers and idlers: For both carrying and return runs.

- Wear strips and guide rails.

2. Chutes and Hoppers:

- Lining material to improve flow and reduce wear.

- Impact plates in high-wear areas.

- Flow aids to prevent bridging and ratholing.

3. Silos and Bins:

- Wall linings to improve material flow.

- Cone linings to facilitate complete discharge.

4. Transfer Points:

- Wear liners in high-impact areas.

- Dust containment systems.

5. Truck and Railcar Linings:

- To facilitate easier unloading and reduce material buildup.

6. Screening and Classifying:

- Screen panels for sizing and separating materials.

7. Vibratory Feeders and Conveyors:

- Trough linings to reduce wear and improve flow.

8. Bucket Elevators:

- Bucket linings to reduce wear and material buildup.

9. Screw Conveyors:

- Trough linings and wear strips.

10. Pneumatic Conveying Systems:

- Pipe linings to reduce wear in bends and transitions.

Benefits of UHMW PE in bulk material handling:

- Abrasion Resistance: Extends equipment life in high-wear applications.

- Low Friction: Improves material flow, reduces power consumption.

- Impact Resistance: Absorbs shocks from falling material.

- Non-Stick Properties: Prevents material buildup, reduces cleaning needs.

- Noise Reduction: Dampens sound from material impacts.

- Chemical Resistance: Suitable for handling various materials including corrosive substances.

- Lightweight: Easier to install and handle compared to steel liners.

- Self-Lubricating: Requires no additional lubrication.

- FDA Compliance: Certain grades are food-safe for handling edible materials.

- Cost-Effective: Offers long-term savings through reduced maintenance and extended equipment

life.

Considerations for implementation:

- Proper thickness selection based on wear expectations.

- Appropriate attachment methods (mechanical fastening, adhesive bonding, etc.).

- Regular inspection and maintenance schedules.

- Potential for electrostatic charge buildup in some applications.

- Temperature limitations compared to some metal alternatives.

Specific Applications by Industry:

- Mining: Ore chutes, conveyor components, truck bed linings.

- Agriculture: Grain handling systems, fertilizer handling equipment.

- Food Processing: Hoppers, chutes, and conveyors for ingredients.

- Chemical Industry: Corrosion-resistant linings for material transport.

- Recycling: Wear components in sorting and processing equipment.

- Power Generation: Coal and ash handling systems.

- Ports and Terminals: Ship loaders/unloaders, transfer points.

UHMW PE’s versatility makes it an excellent choice for many bulk material handling applications, particularly where abrasion resistance, low friction, and material release properties are crucial.