General Engineering

UHMW PE (Ultra-High Molecular Weight Polyethylene) sheets and idlers are widely used in general engineering applications due to their excellent properties. Here’s an overview of their usage in various engineering fields:

1. UHMW PE Sheets in General Engineering:

Applications:

a) Wear Plates:

- Lining for chutes, hoppers, and bins.

- Protective surfaces in high-wear areas.

b) Sliding Surfaces:

- Low-friction components in machinery.

- Guide rails and wear strips.

c) Cutting Boards:

- Food processing equipment.

- Industrial cutting surfaces.

d) Noise Reduction:

- Sound dampening panels.

- Vibration isolation pads.

e) Chemical Containment:

- Lining for tanks and containers.

- Spill containment areas.

f) Machine Guards:

- Protective barriers around moving parts.

g) Conveyor Components:

- Skirting, return rollers, and slider beds.

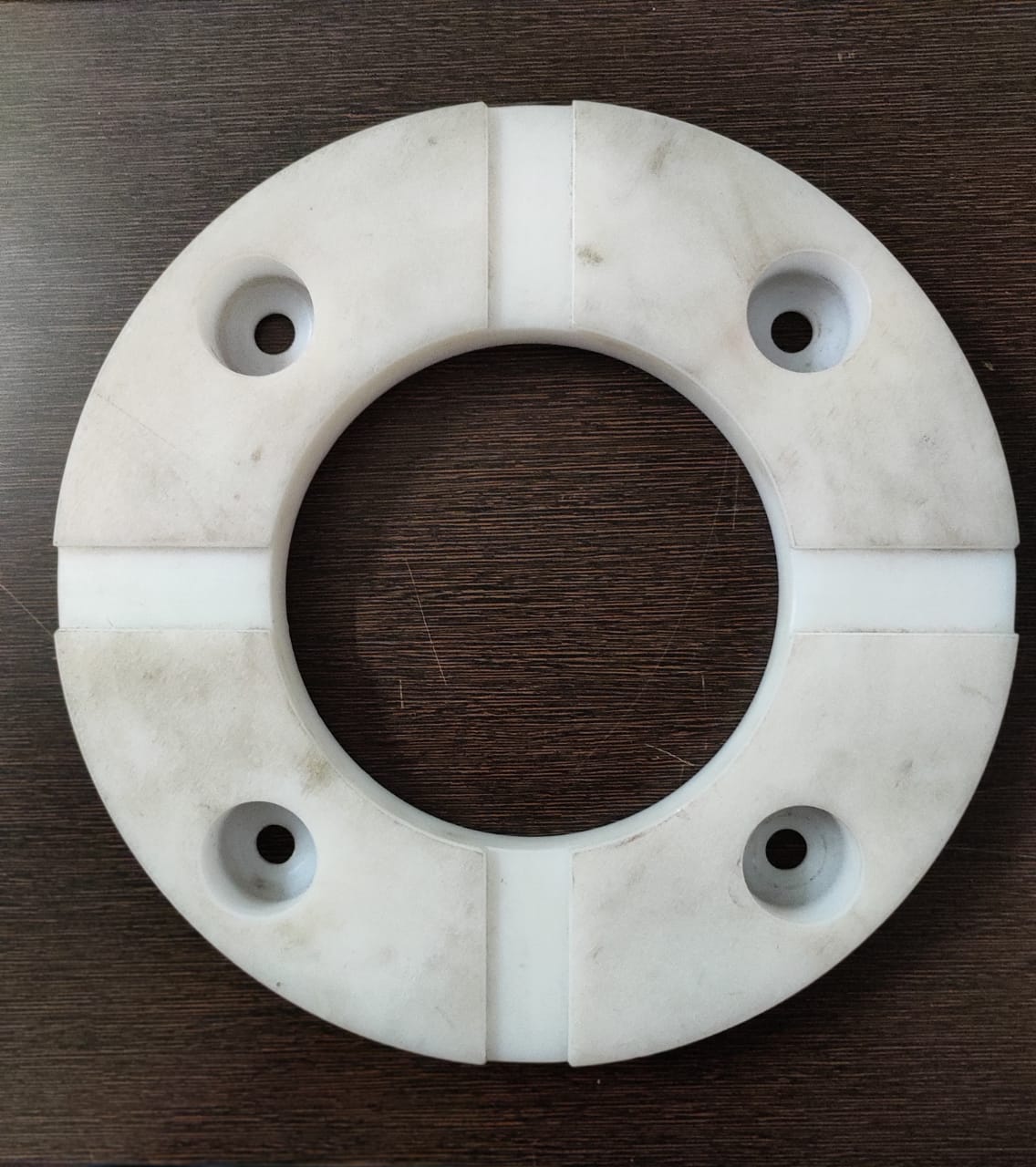

h) Bushings and Bearings:

- Self-lubricating components in low-speed applications.

Benefits:

- High abrasion resistance.

- Low coefficient of friction.

- Chemical resistance.

- Impact resistance.

- Noise reduction properties.

- FDA compliance (for food-grade applications).

- Lightweight compared to metals.

Design Considerations:

- Thickness selection based on load and wear expectations.

- Proper attachment methods (mechanical fastening, adhesive bonding).

- Thermal expansion considerations.

- UV stability for outdoor applications.

UHMW PE Idlers in General Engineering:

Applications:

a) Conveyor Systems:

- Carrying idlers for supporting conveyor belts.

- Return idlers for the return run of belts.

b) Material Handling Equipment:

- Guide rollers in sorting and distribution systems.

c) Packaging Machinery:

- Product transport rollers.

d) Textile Industry:

- Yarn guide rollers.

e) Paper and Printing:

- Web handling rollers.

f) Automotive Manufacturing:

- Assembly line rollers.

g) Food Processing:

- Conveyor rollers in clean environments.

Benefits:

- Low rolling resistance.

- Quiet operation.

- Corrosion resistance.

- Lightweight.

- Self-lubricating properties.

- Abrasion resistance.

- Easy to clean (important for food and pharmaceutical applications).

Design Considerations:

- Load capacity calculations.

- Rotational speed limits.

- Proper sizing for specific applications.

- Bearing selection for mounting.

- Static dissipative grades for applications requiring ESD protection.

Implementation in Both Cases:

1. Material Selection:

- Choose appropriate grade based on specific application requirements.

2. Fabrication:

- UHMW PE can be machined, welded, and thermoformed.

3. Installation:

- Proper mounting to ensure alignment and performance.

4. Maintenance:

- Regular inspection for wear and damage.

- Easy to clean with water and mild detergents.

5. Replacement:

- Typically longer service life compared to metal or rubber alternatives.

Advantages in General Engineering:

- Reduced maintenance and downtime.

- Energy savings due to low friction.

- Improved equipment longevity.

- Versatility across various industries and applications.

Limitations:

- Temperature limitations (not suitable for very high-temperature applications).

- Lower load-bearing capacity compared to some metals.

- Potential for static buildup in some applications.

UHMW PE sheets and idlers offer significant advantages in many general engineering applications, particularly where low friction, wear resistance, and chemical resistance are important. Their use can lead to improved equipment performance, reduced maintenance, and longer service life in a wide range of industrial settings.