Glass Manu..

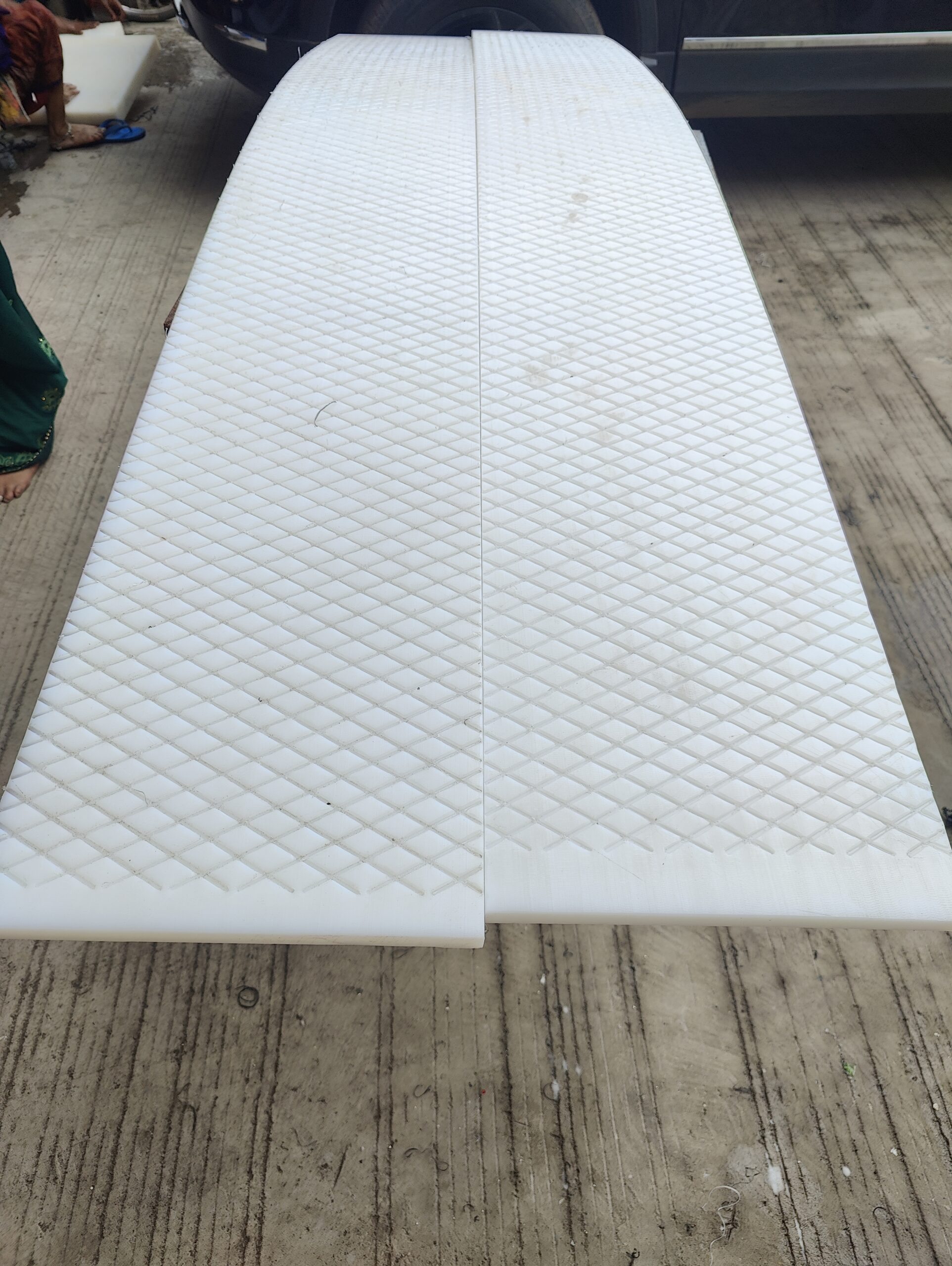

UHMW PE (Ultra-High Molecular Weight Polyethylene) is used in various applications within the glass manufacturing industry due to its unique properties. Here’s an overview of its usage in this sector:

1. Material Handling:

- Lining of hoppers and chutes for raw materials (sand, soda ash, limestone).

- Conveyor components for transporting raw materials and cullet (recycled glass).

- Wear strips and guide rails in production lines.

2. Batch House Operations:

- Lining of mixing and blending equipment.

- Wear plates in batch chargers.

- Components in weighing and dosing systems.

3. Furnace Area:

- Insulation components (where temperature allows).

- Wear parts in burner systems.

- Lining of cooling water pipes.

4. Forming Area:

- Guide rails and wear strips for glass transport.

- Components in IS (Individual Section) machines.

- Mold cooling system parts.

5. Annealing Lehr:

- Conveyor components in the annealing lehr.

- Wear strips and guides for product movement.

6. Inspection and Packaging:

- Guide rails in inspection lines.

- Wear components in sorting and packaging equipment.

7. Cullet Handling:

- Lining of cullet crushers and screens.

- Wear plates in cullet return systems.

8. Dust Control:

- Lining of dust collection systems.

- Components in air filtration equipment.

Benefits of UHMW PE in glass manufacturing:

1. Abrasion Resistance:

- Withstands wear from abrasive raw materials and glass particles.

2. Chemical Resistance:

- Resists degradation from various chemicals used in glass production.

3. Low Friction:

- Improves material flow and reduces energy consumption.

4. Noise Reduction:

- Dampens sound from material impacts and movement.

5 . Non-Stick Properties:

- Prevents buildup of materials, reducing maintenance needs.

6. Impact Resistance:

- Absorbs shocks and impacts in material handling systems.

7. Lightweight:

- Easier to install and handle compared to metal components.

8. Temperature Resistance:

- Suitable for many areas of glass plants (except very high-temperature zones).

9. Non-Contaminating:

- Does not introduce impurities into the glass production process.

10. Cost-Effective:

- Offers long-term savings through reduced maintenance and extended equipment life.

Considerations for implementation:

- Temperature limitations (not suitable for direct contact with molten glass).

- Proper grade selection based on specific application requirements.

- Regular inspection and maintenance schedules.

- Potential for static buildup in some applications (may require antistatic additives).

- Proper attachment methods to ensure secure installation.

UHMW PE’s combination of wear resistance, chemical inertness, and low friction make it particularly valuable in the glass manufacturing industry, especially in areas involving raw material handling, product transport, and wear protection.