Dock Fenders

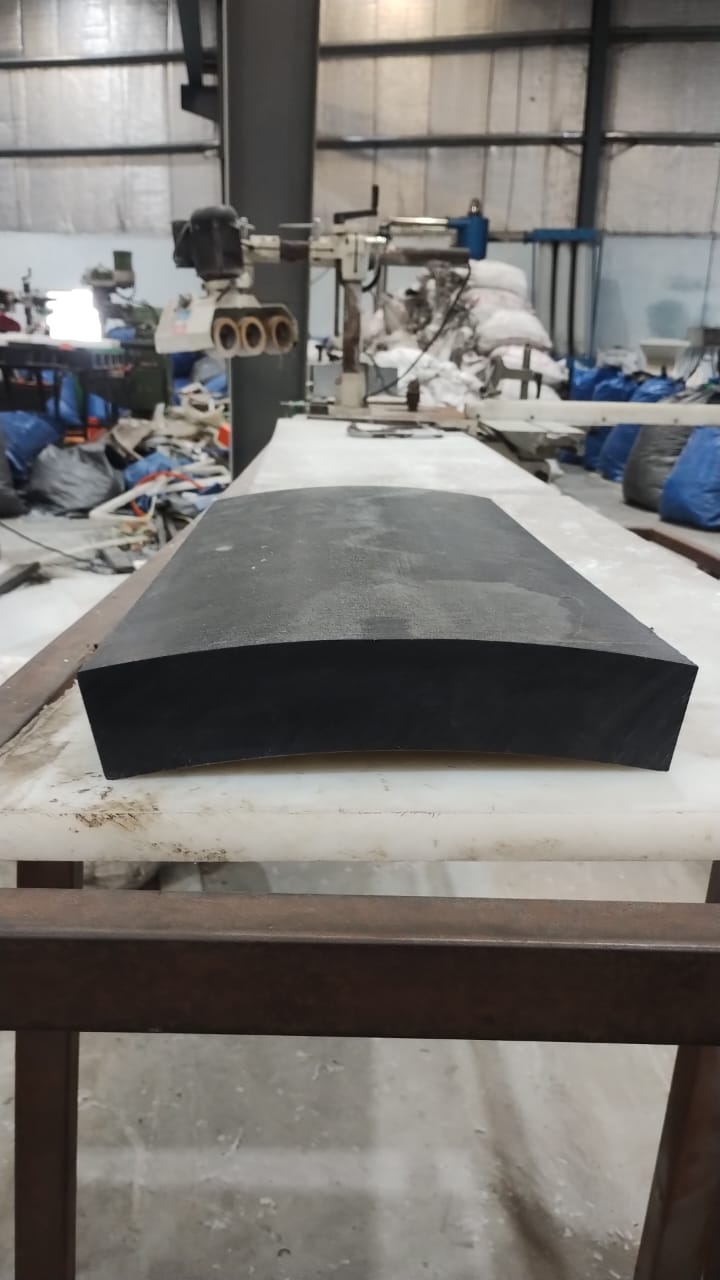

UHMW PE (Ultra-High Molecular Weight Polyethylene) facia pads are an important component in dock fender systems, providing protection and enhancing the performance of marine berthing structures. Here's a comprehensive overview of UHMW PE facia pads in dock fenders:

1. Function:

- Act as the contact surface between ships and the dock structure.

- Distribute impact forces over a larger area.

- Reduce friction during vessel movement along the berth.

2. Applications:

- Commercial ports and harbors.

- Naval bases.

- Ferry terminals.

- Oil and gas terminals.

- Cruise ship terminals.

3. Benefits of UHMW PE Facia Pads:

a) Low Friction:

- Reduces wear on ship hulls.

- Minimizes stick-slip effect during berthing and unberthing.

b) Impact Resistance:

- Absorbs and distributes berthing forces.

- Protects both the vessel and the dock structure.

c) Abrasion Resistance:

- Long service life in harsh marine environments.

d) Chemical Resistance:

- Withstands exposure to seawater, oils, and marine pollutants.

e) UV Resistance:

- Maintains properties under prolonged sun exposure (with appropriate additives).

f) Low Maintenance:

- Doesn’t corrode or rot.

- Easy to clean and inspect.

g) Cost-Effective:

- Long lifespan reduces replacement frequency.

h) Environmental Considerations:

- Doesn’t leach harmful substances into marine environments.

- Potentially recyclable at end of life.

4. Design Considerations:

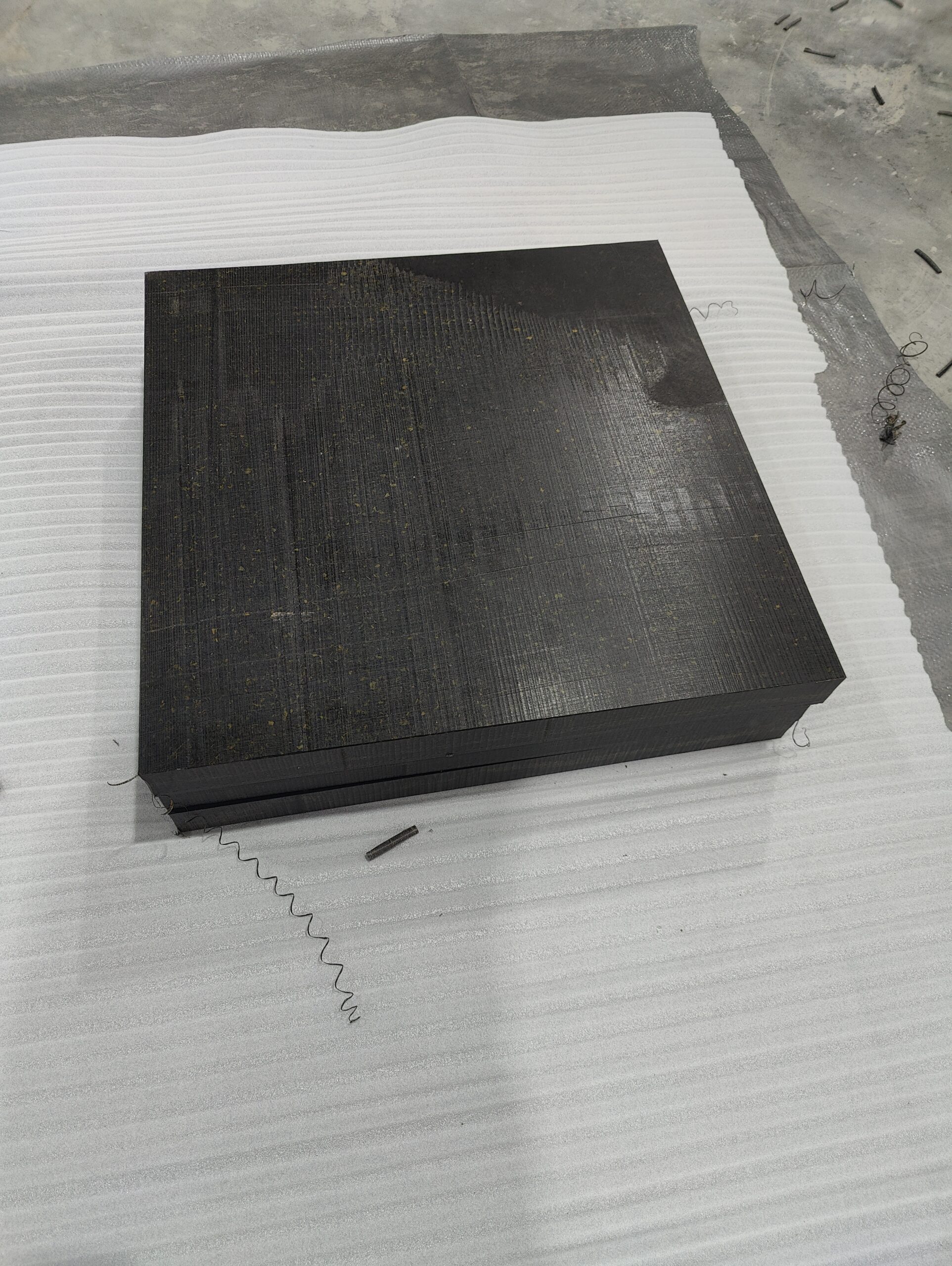

a) Thickness:

- Typically ranges from 1″ to 4″, depending on application.

b) Size:

- Custom-cut to fit specific fender systems.

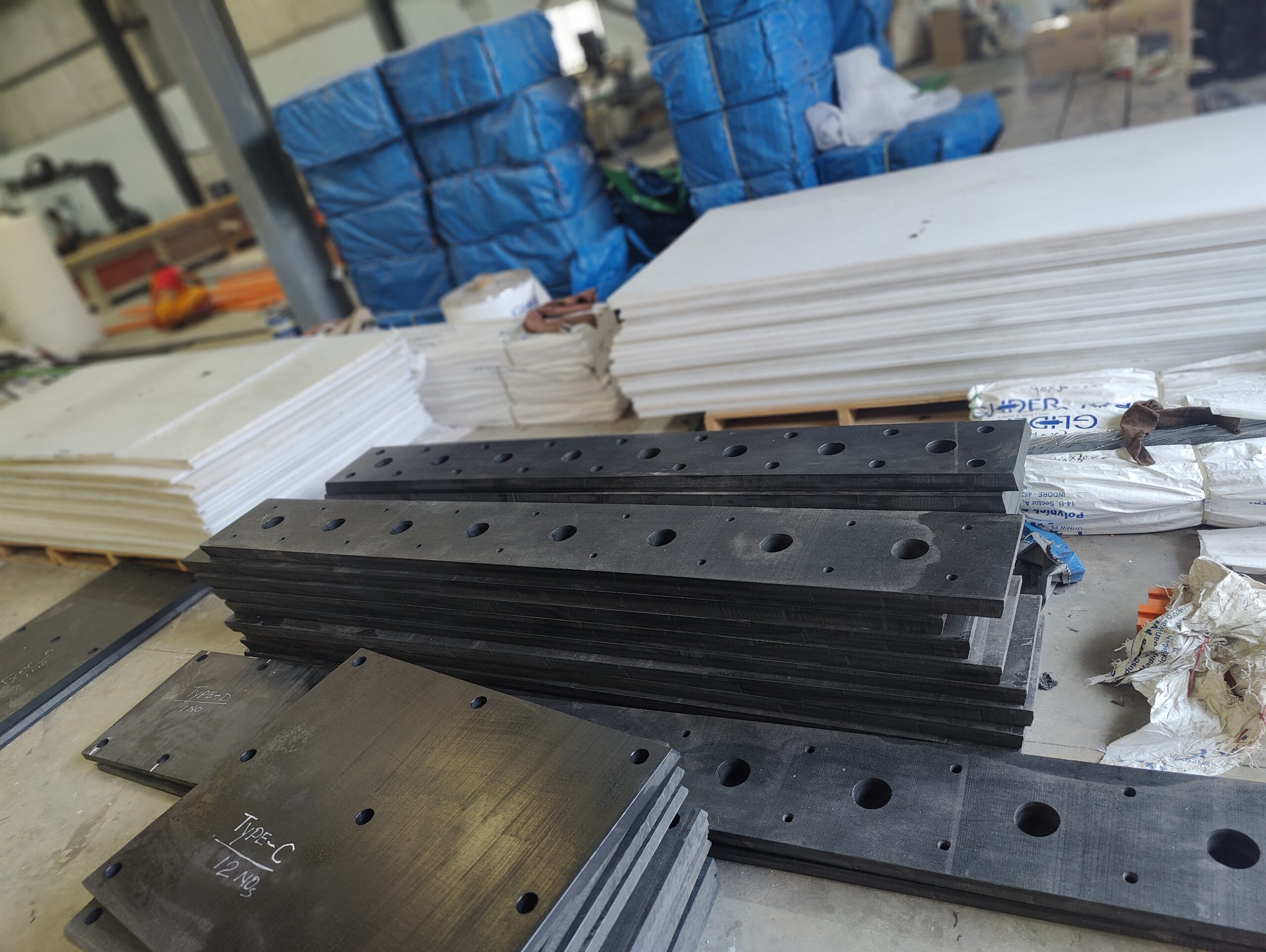

c) Attachment Methods:

- Bolted connections with countersunk holes.

- Adhesive bonding in some applications.

d) Edge Design:

- Often beveled or rounded to prevent catching on ship protrusions.

e) Surface Texture:

- Can be smooth or textured depending on friction requirements.

f) Color:

- Often black, but can be produced in other colors for visibility or aesthetics.

5. Integration with Fender Systems:

a) Rubber Fenders:

- Applied to the face of rubber elements (e.g., cone fenders, cell fenders).

b) Foam-Filled Fenders:

- Used as the outer layer on foam-core fenders.

c) Pneumatic Fenders:

- Can be used as wear pads on floating pneumatic systems.

6. Performance Factors:

a) Energy Absorption:

- Works in conjunction with the main fender element.

b) Reaction Force:

- Helps distribute forces to prevent damage to the vessel or structure.

c) Hull Pressure:

- Designed to keep hull pressures within acceptable limits.

7. Installation and Maintenance:

a) Installation:

- Often factory-fitted to fender elements.

- Can be field-installed or replaced.

b) Inspection:

- Regular checks for wear, damage, or loosening of fasteners.

c) Cleaning:

- Periodic cleaning to remove marine growth or contamination.

8. Considerations for Harsh Environments:

a) Ice Conditions:

- Special grades of UHMW PE for improved impact resistance in icy waters.

b) High-Temperature Regions:

- Selection of appropriate grades to maintain properties in hot climates.

9. Industry Standards:

- Should comply with PIANC (The World Association for Waterborne Transport Infrastructure) guidelines.

- May need to meet specific port authority requirements.

UHMW PE facia pads play a crucial role in modern dock fender systems, offering a combination of low friction, high wear resistance, and excellent impact absorption. Their use contributes to safer berthing operations and reduced maintenance costs for both vessels and port infrastructure.