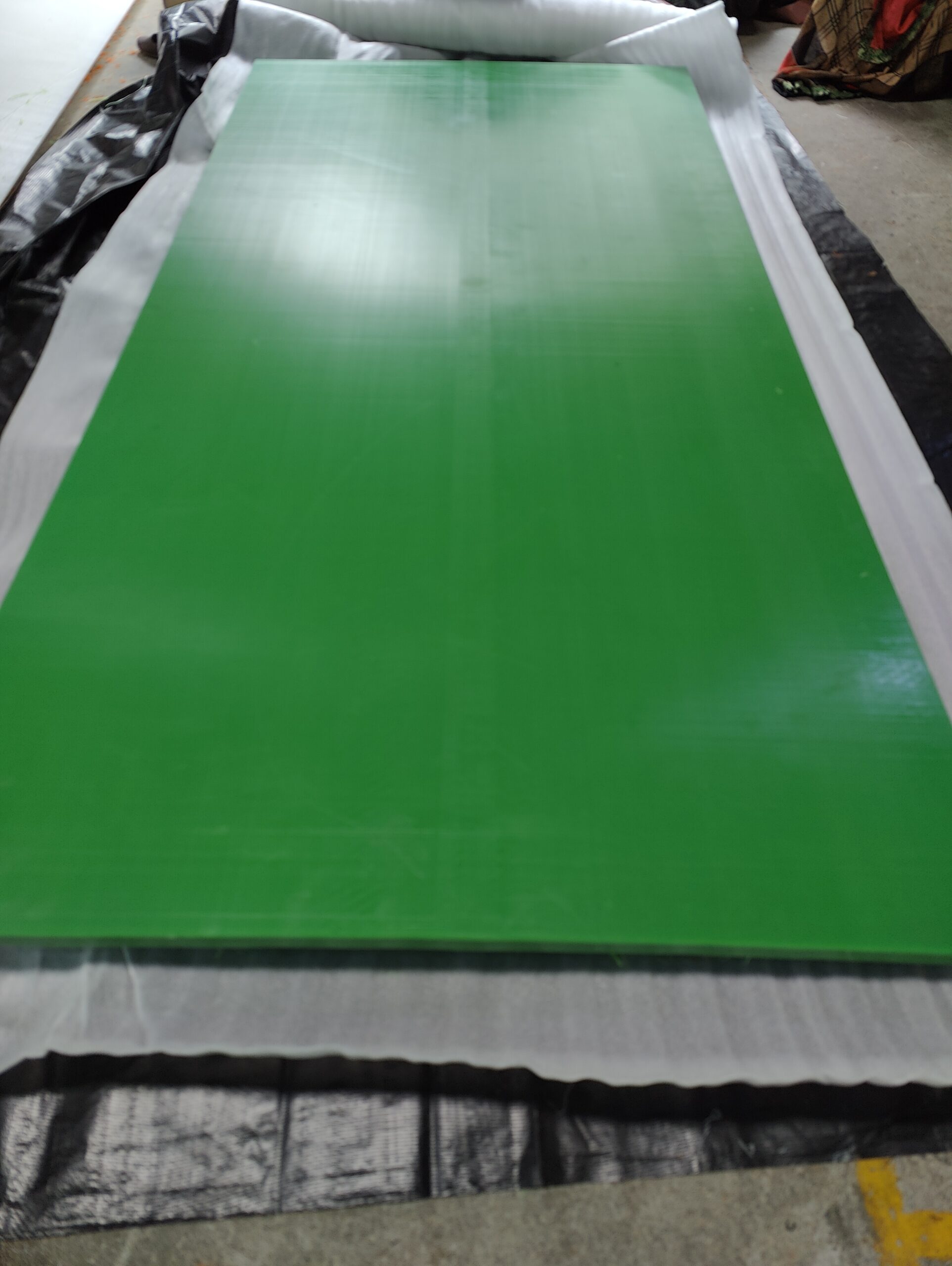

POLYPICK LINERS

Most of the raw materials require cool, dry conditions for storage, and should be used in strict rotation according to age. Rotation is must to avoid sticking of raw material to the storage body. The stock room and method of storage is designed to felicitate the observance of hygiene and safety. The containers used for the storage of bulk solids are usually called Bins, Bunkers, Silos or tanks. These Silos / Bunkers are made of either steel or permanent structure line RCC.

One of the serious causes for materials failure is Wear. It affects the reliability and lifetime of material leading to a number of economic losses. Wearing of metal is one of major problems that occur during material discharge from silos. To minimize damage of metal, liners are used which are replaceable and prevents the equipment from material wear out. Generally Polymer Liner – UHMW PE made by Polypick is being used as liner material for bunkers because of its high strength, high corrosion resistance and very low wear properties.

The Silos, Hoppers are often choked by the moisture present in the material. This decreases the material flow and gradually jams the entire process. The Corrosive material corrodes the body and needs frequent replacement. The Polytron Sheets are used to line the surface to have smooth flow in. With very high impact strength, the POLYTRON liners safeguard the main body and can easily be replaced.

POLYTRON Ultra-high-molecular-weight polyethylene (UHMW-PE) has certain physical properties that are beneficial for bulk solids handling. As a result, it’s often used to line chutes, hoppers, bins, vibratory feeders, drag conveyors, truck beds, ship holds, and bunkers. In many cases, UHMW-PE‘s properties make it more suitable for an application than steel or other types of liners. The physical properties of UHMW-PE include:

- Low coefficient of friction, which improves the flow of a bulk solid

- Excellent abrasion resistance from many bulk solids sliding in chutes or hoppers

- High impact resistance when struck with blunt objects, even at low temperatures

- Zero moisture absorption, which keeps bulk solids from freezing to the liner’s surface.

- Excellent corrosion resistance.

- Light weight (one-eighth the weight of steel), which makes it easy for workers to handle and install sheets of UHMW-PE.

- Easy fabrication using standard woodworking tools.

- Easy formation into troughs or conical hoppers without the need for special forming equipment.

- Wide temperature range capability from – 250°C to 65°C.

UHMW-PE’s low coefficient of friction and high abrasion and impact resistance are the most important properties for handling bulk solids. The following explains how these properties relate to material handling.

Coefficient of Friction:

UHMW-PE has a very low coefficient of friction; its wax-like surface tends to promote, rather than obstruct, flow. This makes UHMW-PE an ideal liner for handling cohesive bulk solids.

Lining chutes and hoppers with UHMW-PE often allows the structures to be built with shallower slope angles, resulting in shorter structures, less reworking (in the case of retrofits), and reduced costs. For example, unlined ship holds usually require that the steel hopper walls be as steep as 55 degrees from the horizontal to get the bulk solid to flow. When UHMW-PE liners are used it’s possible to design the hopper walls with a 37-degree slope from the horizontal. Most 10-meter-long dump trailers with UHMW-PE liners require only a 75 per cent scope extension to dump a bulk solid load. In comparison, unlined trailers require a 100 per cent scope extension.

Abrasion Resistance

It’s important to consider abrasive wear of equipment when storing and handling bulk solids. Wear tests show that for many bulk solids the installed cost of a UHMW-PE liner is comparable with that of steel liners with the added advantage of a lower coefficient of friction. For example, in a grain company stainless steel and abrasion-resistant steel liners in transfer chutes had to be replaced every two years because of abrasive wear. A premium grade UHMW-PE was installed and showed virtually no wear after the same period.

Impact Resistance

POLYTRON UHMW-PE has excellent impact resistance. Unlike other polymers, UHMW-PE won’t break or shatter when struck with a blunt object, such as a hammer. However, the impact from a blunt object is different from the impact of a bulk solid. When a blunt object strikes UHMW-PE, its surface is temporarily depressed, but it quickly returns to its original thickness. However, when a bulk solid strikes UHMW-PE, the result is a gouging, glancing impact that actually cuts into the surface and begins to remove it.

Different angles of impact have different effects. For example, say a truck bed is being loaded from an overhead chute. The resulting 90 degree angle of impact against the horizontal liner produces less wear on the UHMW-PE surface because the bulk solid covers the liner surface and provides a cushion for the remaining material to strike.

For instance, UHMW-PE has successfully handled bituminous coal with a maximum particle size of 3/8-inch, a high concentration of fines, and a velocity of less than 100 feet per minute.

Zero Water / Moisture Absorption

The long molecular chain of POLYTRON UHMWPE makes it such a unique product that it does not absorb any water or moisture. The hoppers, chutes are mostly chocked due to moisture present in material. The wet material sticks on metal body which jams the flow of material. This leads to lot of problem of removing sticky material, replace of metal body and downtime.

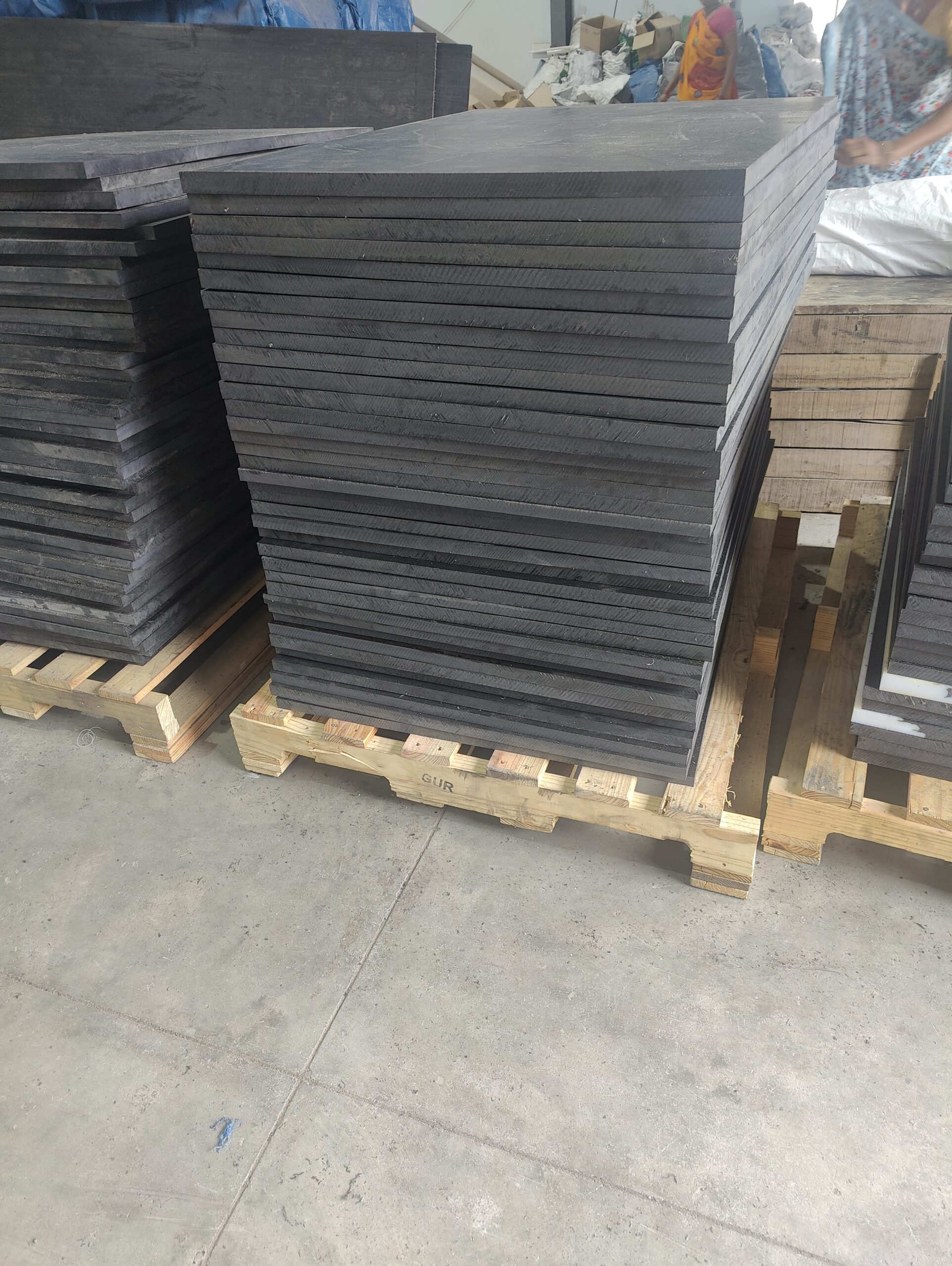

Method of Fixing

Countersunk fasteners, which provide a smooth surface but expose the bolt head to wear. The bolt-head diameter should be a minimum of 6 mm larger than the shank diameter to provide adequate holding strength of the liner. The mounting hole is drilled oversize to allow for expansion and contraction. These fasteners are good for liners upto 10 mm.

Weld washers, which are welded to the substrate with liner in place. The counter sank hole of liner fixed on substrate with welded washer. A compression-fit plug, made of UHMWPE is then driven into the hole over washer, resulting in a smooth, wear resistance surface.

Truck Bed / JCB Liner

Tip Trailers, Dumpers are mostly used in transporting the Moisture/Wet material. The wet material sticks on metal body and sometimes causes tip over. The accident may cause human loss along with machine. In case of Chemical transportation like lime ash, pond ash, salt etc, the vehicle body needs frequent replacement. POLYTRON UHMWPE liners are non-sticky, high abrasion resistance and easy to clean.