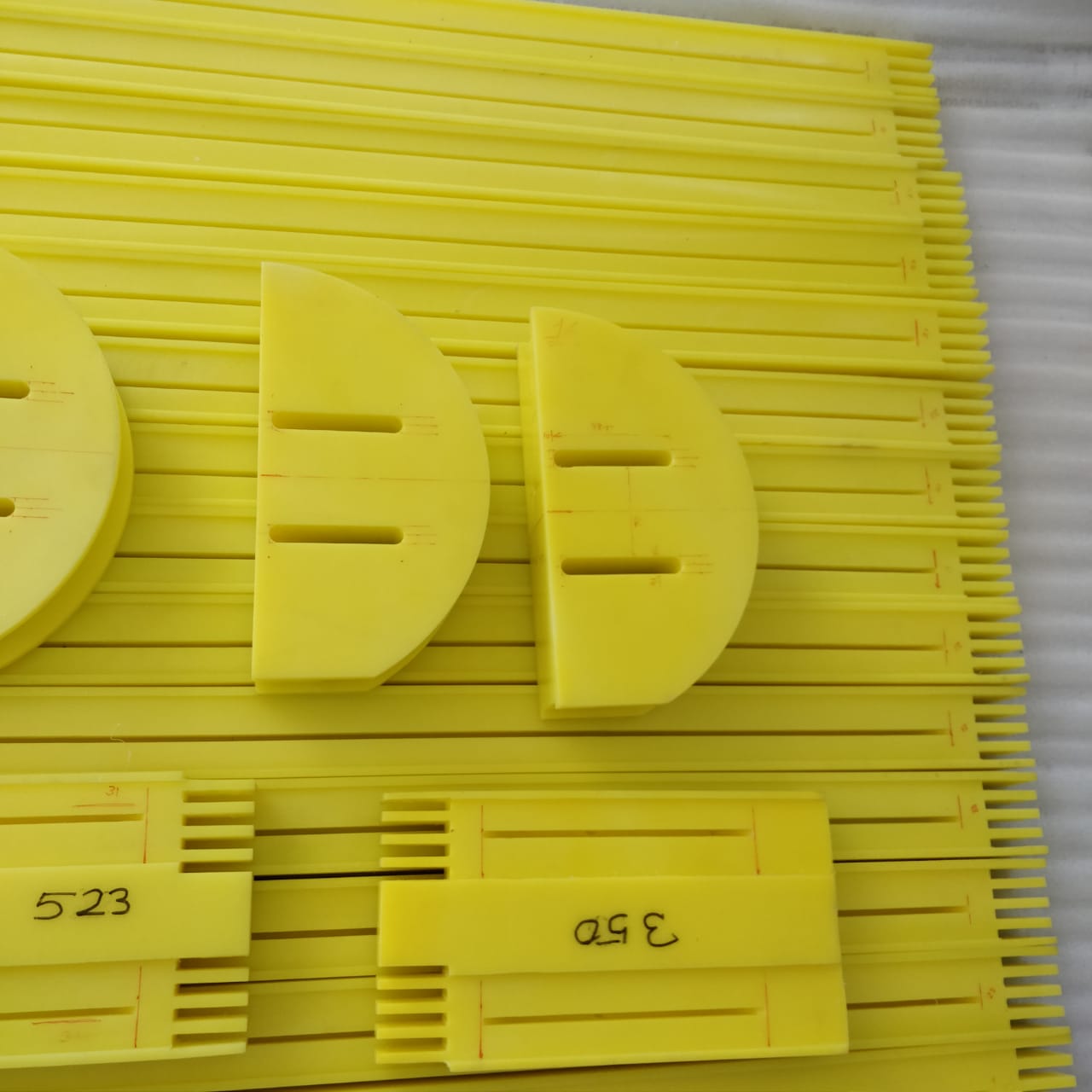

Seal Strips

UHMW PE (Ultra-High Molecular Weight Polyethylene) seal strips play a crucial role in solid-liquid separation plants across various industries. These seal strips are essential components in equipment used for filtering, dewatering, and separating solids from liquids. Here's a comprehensive overview of UHMW PE seal strips in solid-liquid plants:

1. Applications in Solid-Liquid Separation Plants

a) Filter Presses:

- Sealing edges of filter plates.

- Preventing leakage between chambers.

b) Belt Filter Presses:

- Edge seals on belts to contain material.

- Sealing between different pressure zones.

c) Vacuum Filters:

- Sealing edges of filter segments.

- Maintaining vacuum integrity.

d) Centrifuges:

- Sealing rotating components.

- Preventing material bypass.

e) Clarifiers and Thickeners:

- Sealing scraper blades.

- Edge seals on overflow weirs.

f) Screens and Classifiers:

- Sealing screen edges.

- Preventing material bypass around screens.

2. Benefits of UHMW PE Seal Strips

a) Chemical Resistance:

- Withstands exposure to various chemicals and pH levels.

b) Wear Resistance:

- Long service life in abrasive slurry environments.

c) Low Friction:

- Reduces wear on mating surfaces (e.g., filter cloths).

d) Flexibility:

- Conforms to slight irregularities in mating surfaces.

e) Non-Stick Properties:

- Resists buildup of solids, facilitating cleaning.

f) FDA Compliance:

- Suitable for food and pharmaceutical applications.

g) Cost-Effective:

- Long service life reduces replacement frequency.

h) Easy Fabrication:

- Can be easily cut, drilled, and shaped to fit specific equipment.

3. Design Considerations

a) Profile Shape:

- Customized to fit specific equipment geometries.

- May include features like lips, grooves, or reinforced edges.

b) Thickness and Width:

- Determined by the specific application and sealing requirements.

c) Mounting Method:

- May include holes for bolting, grooves for sliding insertion, or adhesive bonding.

d) Compression Characteristics:

- Designed to maintain sealing under specified pressures.

e) Edge Design:

- Beveled or rounded edges to prevent damage to filter media.

4. Installation and Maintenance

a) Installation:

- Often designed for easy replacement without major equipment disassembly.

- May require specific tools or techniques for proper fitting.

b) Inspection:

- Regular checks for wear, deformation, or damage.

c) Cleaning:

- Periodic cleaning to remove build-up and maintain sealing efficiency.

d) Replacement:

- Timely replacement to prevent leaks and maintain separation efficiency.

5. Performance Factors

a) Sealing Efficiency:

- Ability to prevent leakage or bypass of materials.

b) Wear Rate:

- Longevity in continuous operation.

c) Chemical Compatibility:

- Resistance to process chemicals and cleaning agents.

d) Temperature Resistance:

- Ability to maintain properties across the operating temperature range.

6. Industry-Specific Considerations

a) Mining and Mineral Processing:

- Resistance to highly abrasive slurries.

b) Wastewater Treatment:

- Compatibility with biological processes and chemicals.

c) Food and Beverage:

- Compliance with food safety regulations.

d) Chemical Processing:

- Resistance to aggressive chemicals and solvents.

e) Pulp and Paper :

- Ability to handle fibrous materials and process chemicals.

7. Advantages over Traditional Materials

a) vs. Rubber:

- Better chemical resistance and longer life in many applications.

b) vs. Metal:

- Lower friction, reducing wear on filter media.

c) vs. Other Plastics:

- Superior wear resistance and impact strength.

8. Limitations

- Not suitable for very high-temperature applications.

- May require more frequent replacement in extremely abrasive conditions.

- Potential for cold flow under high, constant loads.

UHMW PE seal strips are critical components in solid-liquid separation plants, contributing to improved efficiency, reduced maintenance, and enhanced product quality. Their unique combination of properties makes them well-suited for the challenging environments found in these applications.