Power Plants

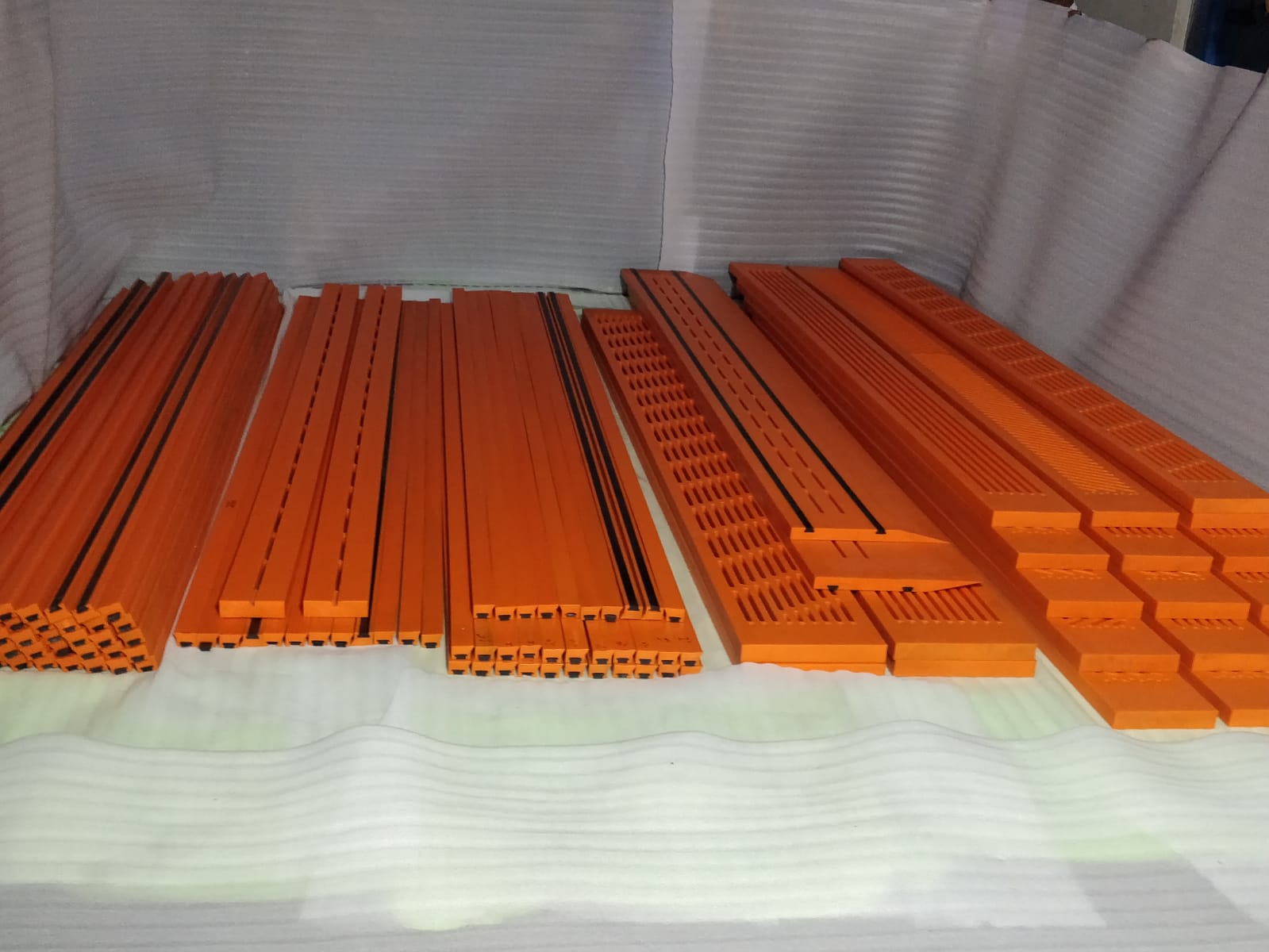

UHMW PE (Ultra-High Molecular Weight Polyethylene) liners are extensively used in the coal industry due to their excellent properties. Here’s an overview of their applications and benefits:

1. Coal Chutes and Hoppers:

- Liners reduce friction, preventing coal from sticking and ensuring smooth flow.

- They protect the underlying structure from abrasive wear, extending equipment life.

2. Conveyor Systems:

- UHMW PE is used to line conveyor troughs, skirtboards, and transfer points.

- It reduces friction, minimizes dust generation, and prevents material buildup.

3. Truck and Rail Car Linings:

- Liners facilitate easier unloading of coal, reducing carryback.

- They protect vehicle beds from wear and corrosion.

4. Bunker and Silo Linings:

- UHMW PE liners ensure consistent coal flow and prevent bridging or rat-holing.

- They protect concrete or steel structures from abrasion and chemical attack.

5. Screens and Classifiers:

- UHMW PE screen panels offer longer wear life compared to metal screens.

- They reduce noise and are less prone to blinding or pegging.

6. Coal Preparation Plants:

- Liners are used in various equipment like flotation cells, cyclones, and dewatering screens.

- They protect against both abrasion and chemical attack from coal slurries.

7. Stackers and Reclaimers:

- UHMW PE linings on buckets and chutes reduce wear and improve material flow.

8. Dust Suppression Systems:

- Lining spray hoods and enclosures helps prevent buildup and ensures proper functioning.

9. Piping Systems:

- UHMW PE pipes and liners are used for transporting coal slurries and tailings.

Benefits of UHMW PE liners in the coal industry:

- Abrasion Resistance: Extends equipment life in high-wear applications.

- Low Friction: Improves material flow and reduces power consumption.

- Impact Resistance: Withstands heavy loads and impacts from coal and rock.

- Chemical Resistance: Resists degradation from acids and other chemicals present in coal.

- Noise Reduction: Dampens sound from impacts and material flow.

- Non-Stick Properties: Prevents coal buildup and reduces cleaning requirements.

- Lightweight: Easier to install and handle compared to steel liners.

- Temperature Resistance: Performs well in both cold and moderately high temperatures.

- Cost-Effective: While initial costs may be higher, long-term savings are realized through reduced maintenance and extended equipment life.

Considerations for implementation:

- Proper thickness selection based on wear expectations.

- Appropriate attachment methods (mechanical fastening, adhesive bonding, etc.).

- Regular inspection and maintenance schedules.

- Potential for electrostatic charge buildup in some applications.

Fly ash, a byproduct of coal combustion in power plants, presents unique challenges in material handling due to its abrasive nature and potential for buildup. UHMW PE pipes offer several advantages in this application:

1. Abrasion Resistance:

- UHMW PE’s high wear resistance helps protect the pipes from the abrasive fly ash particles, extending system lifespan.

- This reduces maintenance frequency and replacement costs compared to metal pipes.

2. Low Friction:

- The smooth interior surface of UHMW PE pipes reduces friction, facilitating easier flow of fly ash.

- This property helps prevent buildup and clogging, a common issue with fly ash handling.

3. Chemical Resistance:

- UHMW PE is resistant to many chemicals, protecting the pipes from potential corrosive elements in the fly ash.

4. Lightweight:

- Easier installation and handling compared to metal pipes.

- Reduces structural load in elevated installations.

5. Flexibility:

- UHMW PE pipes can handle some flexing without damage, useful in systems subject to vibration or movement.

6. Temperature Resistance:

- Can handle the typical temperature range of fly ash handling systems without degradation.

7. Anti-static Properties:

- Some UHMW PE formulations offer anti-static properties, reducing the risk of static electricity buildup.

8. Noise Reduction:

- UHMW PE pipes can help reduce noise in the handling system compared to metal pipes.

9. Customization:

- Can be fabricated into various shapes and fittings to suit specific system designs.

10. Cost-Effective:

- While initial costs may be higher than some alternatives, the long-term durability and reduced maintenance needs often result in lower lifecycle costs.

In fly ash handling systems, UHMW PE pipes are commonly used in:

- Pneumatic conveying systems.

- Slurry transport lines.

- Ash conditioning systems.

- Silo discharge pipes.

When implementing UHMW PE pipes in fly ash handling, it’s important to consider:

- Proper sizing for flow rates and pressure requirements.

- Appropriate connection methods (e.g., flanged, welded).

- Regular inspection for wear, especially in high-impact areas.